Spray Booth Retrofit Systems

Infratech Spray Booth Retrofit Systems allow you to cure high-tech automotive coatings with superior speed, quality, safety, efficiency and control.

Our systems are designed to operate in four independent zones. This multiple zone control gives you the ability to heat a single panel for a simple repair, or to cure a complete repaint. It also enables you to achieve greater energy cost savings by heating only the area that requires curing.

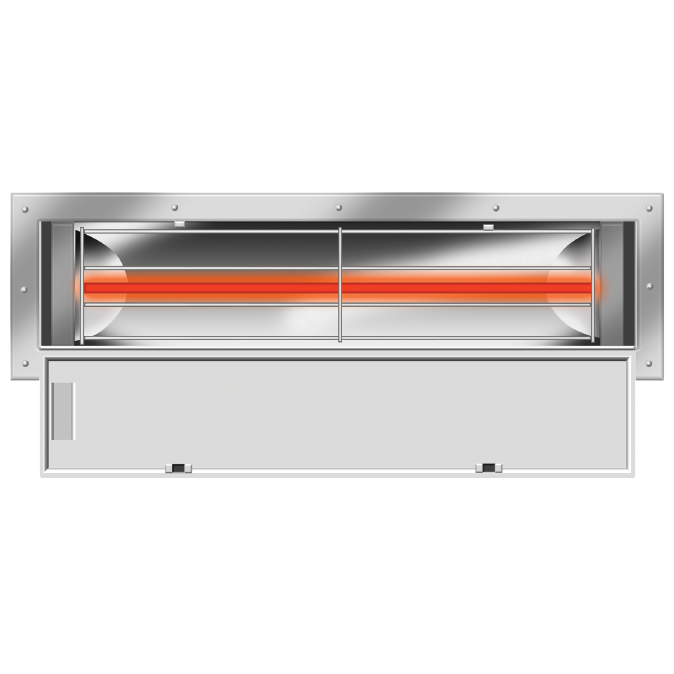

Our systems utilize high-intensity medium wave quartz emitters capable of curing a complete repaint in 20-30 minutes. These quartz emitters are custom manufactured in-house by Infratech to guarantee the exact wavelength (2.35 microns) that is most effective for curing the oxygen/carbon-based (organic) compounds that make up all liquid automotive coatings. They offer a long life expectancy of 5,000 hours. In addition, they utilize narrow energy waves that pass through the air with minimum molecular contact, creating an environment in which the air is always cooler than the liquid coating and substrate. This high-intensity, medium wave heat yields the fastest possible drying time without compromising the quality of the cure. With an Infratech system, you can expect improved gloss, reduced orange peel, superior adhesion and a considerable reduction in energy costs – without the danger of damaging heat-sensitive parts of the car.

For more information about Infratech Spray Booth Retrofit Systems, please contact us.