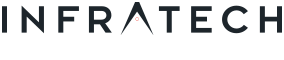

Now there’s a faster, more efficient way to go from zero to dry.

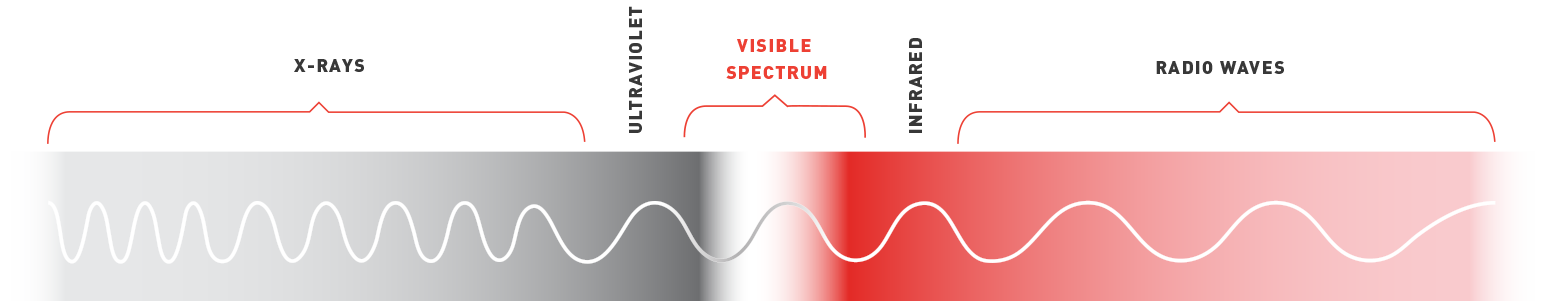

About infrared energy

Electric infrared technology is practical and precise. It works by transferring heat directly to your product, without heating the surrounding air. This offers several benefits, including faster heat transfer and greater control for spot heating. In addition, infrared heat can be significantly more cost-effective than convection heat, largely because it reduces cycle times, can focus energy on the areas to be cured, and does not require an expensive, insulated enclosure to trap and re-circulate heat.

High efficiency. Zero emissions.

Infratech electric infrared products are an environmentally friendly way to reduce energy demand and increase the efficiency of your operations. Unlike natural gas, diesel and propane-fueled equipment, our products are powered by renewable energy sources and generate zero emissions. As a result, you will enjoy faster heating times without NOX, dust, soot, ozone, carbon monoxide or other toxic emissions that are currently regulated, and require permits, reporting logs and specialized monitoring.

Superior finish capabilities.

Infrared heat offers exceptionally fast dry times that are often one-quarter to one-tenth the time needed when air-drying finishes. This technology is also cleaner. Infrared energy requires little to no air-flow, thereby minimizing deposits of contaminants in a finish. The higher curing temperatures created by infrared energy generally yield a higher gloss with less orange peel and better adhesion.

Where to use:

- Automotive refinishing, including primers, base coats, top coats, fillers, fiberglass repair, two component materials with solvent or water-borne formulas. Infrared can be safely used on plastic, aluminum, steel and fiberglass components.

- Wood working, primers, sealers, fillers, toners, stains, top coats, lacquers, water-borne and solvent-based materials, two component materials and special effects materials used over a variety of hard woods, soft woods, plywoods and engineered wood (MDF-style) substrates.

- Other applications include heat-treating, forming plastic components, drying decorative finishes on pottery, glass, composites, wood, metal and plastic.

- Drying common water- and solvent-based adhesives for laminating materials.

- Virtually any low-temperature heat application between 100° F – 500° F can be accelerated with Infratech electric infrared products.